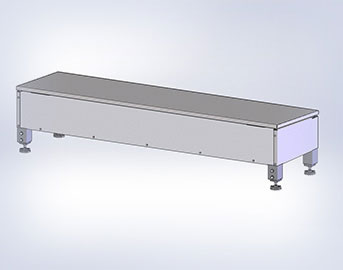

Core elevator and revolving device

The core elevator and revolving device is positioned between the core winder and the core hopper that feeds the rewinder.

By means of the rubber fingers the core elevator and revolving device lifts one core at a time after taking it from cores lined up on the lower plan and discharge it onto the upper plan which is oriented at 90 degrees from the lower plan into the core hopper.

Upon request, the angle between the lower and upper plan can be different from 90 degrees.

Upon request, according to layout needs, the machine can be produced to be positioned either on the right or on the left side.

Benefits

- Belts and all moving parts are completely integrated in order to avoid any contact between operator and moving parts;

- The rubber fingers are strong enough to support the cores but can deflect in case of accidental contact with operator;

- The core winder can be oriented parallel to the line, thus saving floor space;

- Raw material to feed the core winder is closer to the reels transportation area;

- More compact layout.

Technical Specifications

| Core diameter | up to 2’ |

| Core maximum length | 3350 mm |

| Core minimum length | 2250 mm |

| Installed power | 0.2 kW |

| Voltage: | upon request |

| Frequency | upon request |

| Lifting rate | up to 60 cores/min |

| Angle between two plans | up to 90° (different values upon request) |

| Air compressed pressure | 6 bars |

| Air compressed consumption | 50 lt/min |